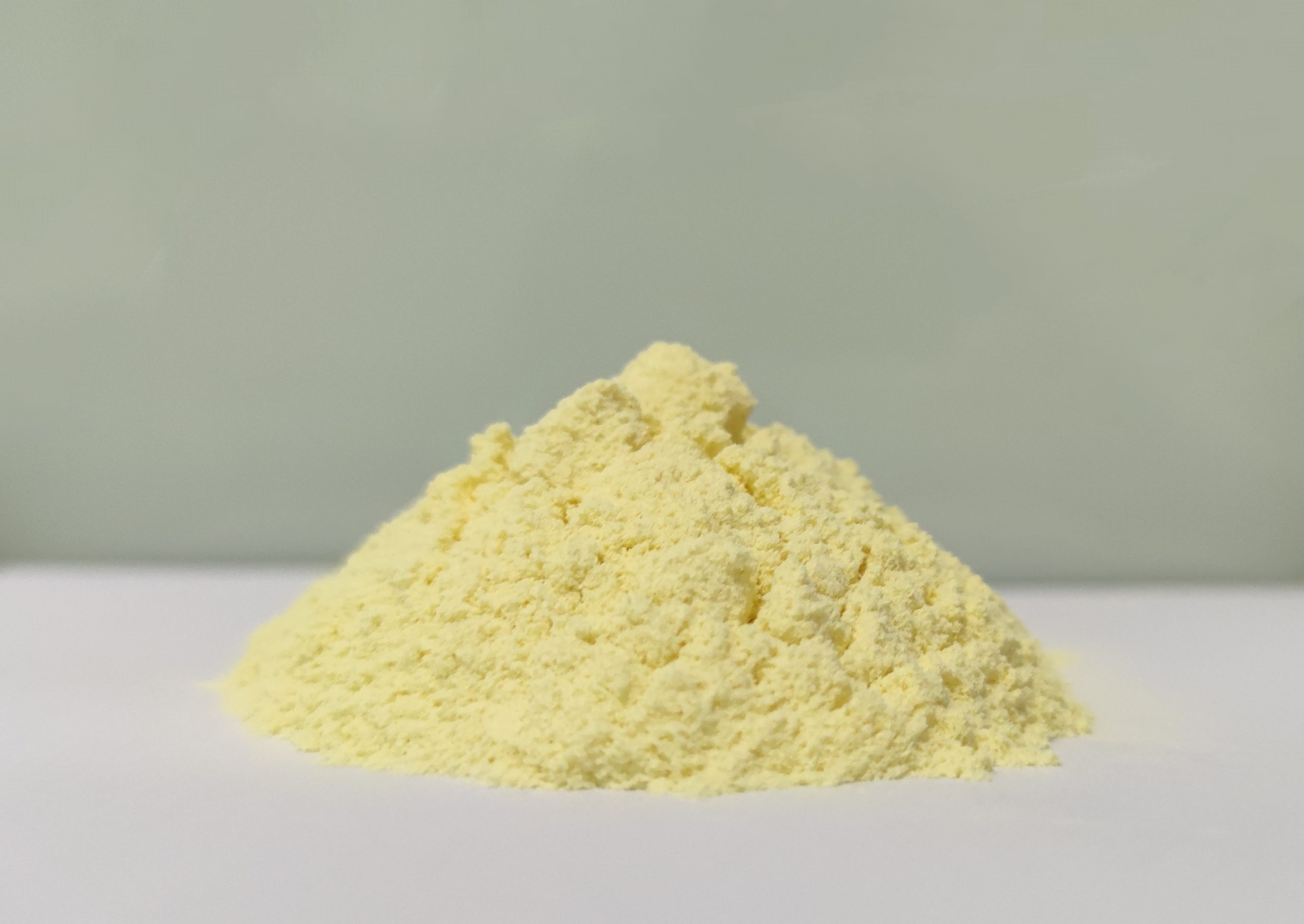

Adding chopped carbon fiber to engineering plastics can significantly improve their tensile strength, flexural strength, and modulus. For example, adding chopped carbon fiber can increase the tensile strength of polyamide (PA) engineering plastics by 30% – 50%. Chopped carbon fiber plays a skeleton like role in plastic matrix, bearing external loads and thus improving overall mechanical performance.

Chopped Carbon fiber can increase the glass transition temperature and thermal deformation temperature of engineering plastics, which enables modified engineering plastics to maintain their shape and properties in high temperature environments.

For applications that require anti-static or conductive properties of engineering plastics, such as preventing static electricity accumulation in electronic device casings or adding chopped carbon fibers in electromagnetic shielding applications, the conductivity of engineering plastics can be effectively improved. By adjusting the amount of carbon fiber added reasonably, the surface resistivity of engineering plastics can be reduced to the ideal range.

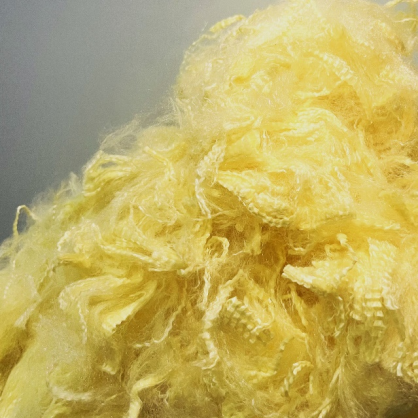

Adding aramid short-cuts to engineering plastics can improve their strength while maintaining a certain level of toughness. Compared to chopped carbon fiber, aramid short-cuts increase strength without making engineering plastics too brittle.

-

Products

-

Application